Galaxy Dimond Plaza, Greater Noida West,

NCR 201009, Republic of India

Friday 09:30am - 05:30pm

Manufacturing

Our robust portfolio of offerings across the O&G, Petrochemicals, defense, space and Fabricators markets includes secure high-end solutions in engineering, IT modernization and mission solutions. Using our expertise and understanding of existing and emerging technologies, we integrate the best components from our own portfolio and our partner ecosystem to deliver innovative, effective and efficient solutions that are critical to achieving our customers' missions.

We are manufacturing Forgings and Flanges with our expertise and understanding the requirement of our clients. We are doing requirement analysis and mapping of the projects.

We are specialized in Project and bulk requirements. We are currently handling in all Grades of materials such as Inconel, Monel, Aluminum, Stainless Steel, Austenitic, Super Austenitic, Duplex / Super Duplex and Carbon Steel.

We have capacity to handle materials upto 72” Dia, thickness upto 500 mm and weight upto 5 MT. We can supply with NACE & HIC requirements. We are familiar with several national and international Design and Technical standards like, ASTM, DIN, AS, EN, JIS, NACE. Our Plant and Machineries details are as below:

RAW MATERIALS :

To provide complete focus on choosing raw materials with the highest quality, the raw material go through inspection of incoming material. With capacity to arrange raw materials in shortest lead time we are the pioneers in the industry.

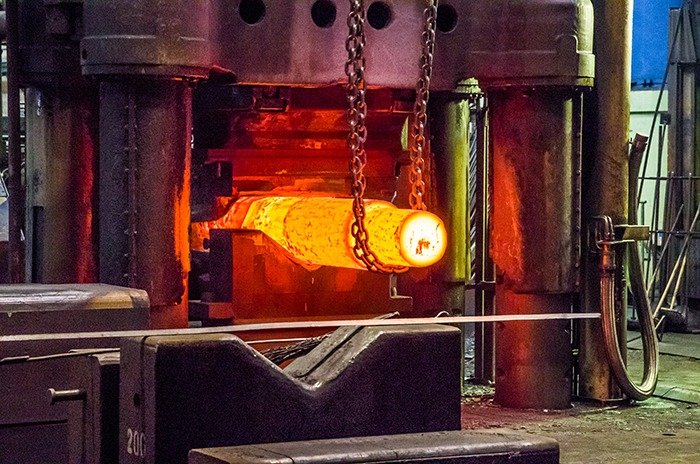

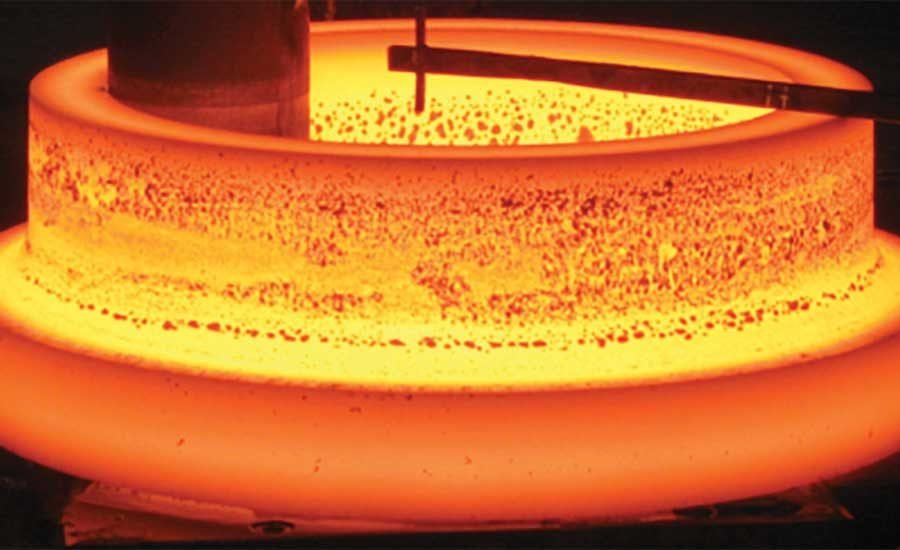

FORGE SHOP :

Our Forged Shop is equipped with Bend Shaw and Steam Forging Hammers capacity of 7MT and 12 MT. We also have forging hammers for making of Rings with capacity of upto 12 MT.

We have oil firing forging furnace with winch arrange of 12 M/T capacity with temperature indicator 0 to 1600 Degree.

MACHINE SHOP :

Our Machine shop is equipped with numbers of CNC, VMC, Lathe, VTL and Radial Drill machines with a capacity to manufacturing upto 72” outer dia.

HEAT TREATMENT :

1. We have oil fired and electrical Heat Treatment Furnace (Boggy Type) with a capacity of 10 MT. <

2. Temperature indicator 0-1200 degree: 4 nos. <

3. Heat Treatment conditions are normalized, Oil Quenching, Solution Annealed. <

4. Separate tanks are available for Oil Quenching and Solution Annealed. <

TESTING FACILITIES :

Our Quality Testing Lab is equipped with Universal Testing machine (Tensile), Impact Test, Notch Cutter, Brinell Hardness Tester, IGC Apparatus, Metallurgical Microscope, small HT Furnace for simulation, PT Examination Kit, Ultrasonic Test Machine, Yoke Machine for MPI Test and PMI Machine. <

|

|

|

|---|

No matter what type of engineering project you have, We can help.

Submit your project today!

Request a Call Back

For Business: For Business inquiry fill our short feedback form or you can also send us an email and we’ll get in touch shortly.

Note: Your details are kept strictly confidential as per our Company Privacy Policy.